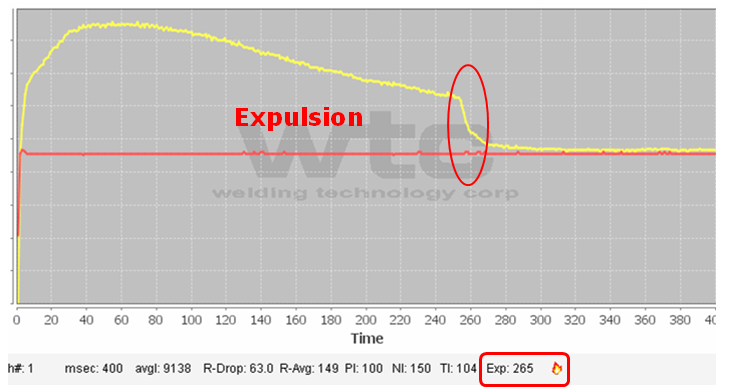

Expulsion is Detectable with RAFT

Sometimes expulsion is not prevalent on the

manufacturing floor but does exist periodically. When

expulsion occurs, there is a sudden reduction of

resistance between the electrodes. In this example,

expulsion was detected at 265mS period of the weld. This

value is recorded and can be reported through the

network system. With this information, the user can pin

point where expulsion exist - to a spot number on a

part, to a specific part, etc... This makes it easier

for the user to address process issues that generate

expulsion conditions.

Also, when using the control in adaptive mode, the

control automatically adjusts itself to produce an

expulsion free weld conditional that the reference weld

is also expulsion free.