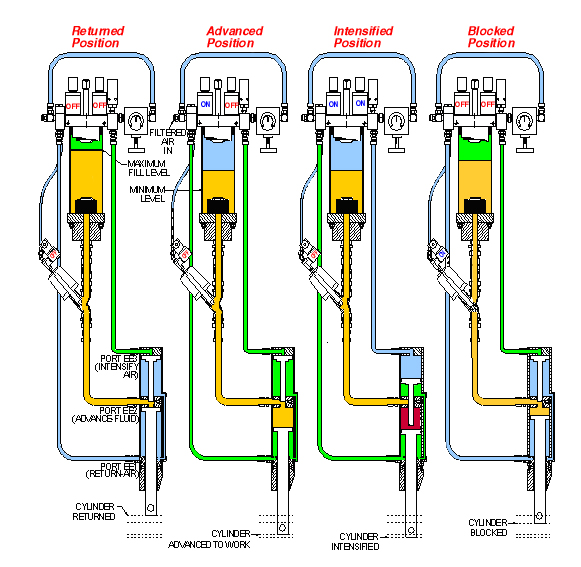

Blocking Feature and Sequence of the "Ohma® Cylinder"

A 2-way valve is incorporated in the fluid line to block fluid return during the return portion of the OHMA cylinder sequence of operation. A normally open blocking valve is usually selected for this option. During the low pressure advance and weld stroke portion of the sequence, the blocking valve remains open (de-energized). At the conclusion of the power stroke (end of weld) the return sequence is initiated. This will cause the gun package to begin to open. Once the desired opening is achieved the blocking valve is closed (energized) to prevent the fluid from reentering the remote fluid reservoir. This action effectively prevents the gun from opening further and maintains this partial opening at a predetermined position. It is important to note that the partial open position is fully adjustable as per the needs of the application. Once the partial opened weld process is completed the blocking valve can remain open to allow the transgun to achieve a fully opened positioned.

The incorporation of a blocking valve can also provide a partial close feature for gun setup needs. The welding control has special parameters for the timing operations of the blocking feature so that the user can preset various positions of cylinder blocked locations The software in the weld control that controls the sequencing operation is well developed to deal with the laws of physics and inertia so that repetitive operations occur.

Legend:

|

Blue: Air |

Yellow: Fluid |

Red: Fluid under Intensified Pressure |

Green: Exhaust |

Centerline (Windsor) Ltd