Sample Case: Setting Up for 5 Stack Ups Using Single Trigger

Step 01

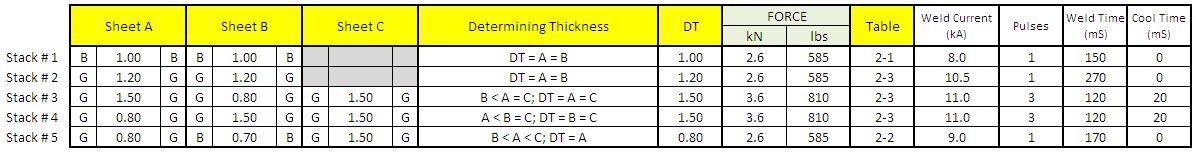

Document the table of the normal constant current schedules that would exist under normal circumstances where a specific weld schedule can be selected. This table is derived from user's database of weld schedules which can differ from one user to another. As you can see, there are variations for welding these five different stacks. Welding force on this table shows some selections requires 2.6 kN and others requiring 3.6 kN. Also the welding current ranges from a low of 8.0kA to as high as 11.0kA and welding times varies as low as single pulses of 150mS to three pulses of totalling 360mS. So clearly, the user would have to select four different schedules to satisfy all these requirements. The procedure will be established for one single schedule with RAFT automatically adapting to extend the welds and boost up current when required.

To Top